First, use many colors to study work. I prefer to use coordinated colors composing on separate sheets, for example, dark blue, light blue, purple, magenta, and pink. I use the darker colors for the words or diagrams, and the lighter colors for decorations. It brightens the entire page and helps to create interest. I avoid using red for writing as a significant area of men are colorblind to red. Red’s and black’s are also “blocking” or “stopping” colors and shades.

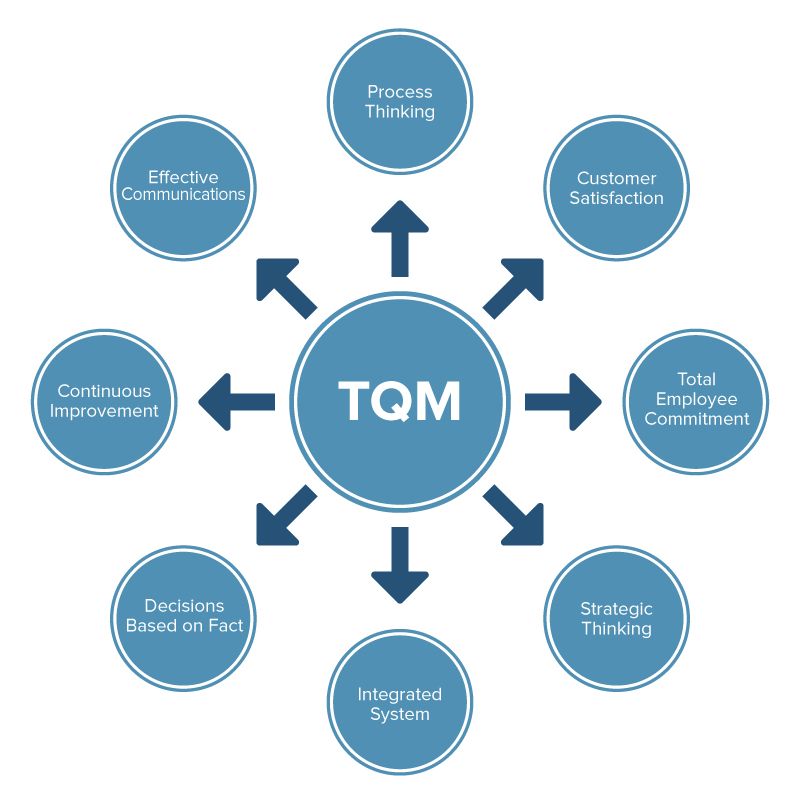

Six Sigma is just not a new, improved version of Total ISO 9001 certification consultants. The two processes have got their similarities, but doesn’t meam they are the actually. TQM is focused more on the actual result and undoubtedly seen other courses improvement while Six Sigma focuses on business success and improving the chances for that success on the much larger scale.

Buttweld – This type of tube by the same process much like the ERW. It starts off as a set sheet of steel, then rolled to create a tube. However, instead making use of an electric welder, the perimeters are heated and fused together, creating the direction. However, this is the least used manufacturing method.

No challenege show up your employment field is, take benefit of social media marketing. Set up a Twitter account, a LinkedIn account and in many cases an employment page on Facebook and employ them to network with prospective employers, prospective employers’ acquaintances, and even other people looking for employment. Not qualified for each job on the market, described may be a little more than thrilled to pass on an employment lead, and you should do the same for them.

Keep the implementation on the six sigma certification methodologies elementary. Don’t try to overdo it with ideas you would likely have in mind that end up being the too complex. There are many complex tools and resources that could be used this particular particular type of training. Keep it simple to off sufficient reason for. You can widen your horizons later. The number one thing just a few ingredients to do is lay the groundwork for existing processes. Following business already been streamlined, place then begin bigger projects.

Measure and understand CTQ factors, which stands for things that are “critical to quality”. This will take into consideration; risk, production, and the ability to produce systems.

As the season’s changed, so did our own products. We sold Christmas trees in the parking lot and we moved the rest of the business within building. Pretty soon, had been peddling Poinsettia’s door to door, times were better back then but To get still making 40 dollars a pop, each time I walked into an opportunity with an armload of plants.