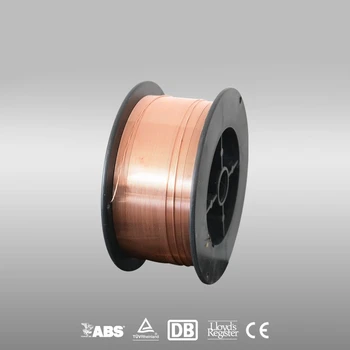

In recent times, the appliance of arc welding processes has been studied as additive manufacturing strategies for metals. Several deoxidizing metals are included similar to aluminum, silicon, titanium, and manganese. Furthermore, are provided the issues demanding particular attention to welding works of assorted stainless steels, similar to austenitic stainless steel, ferritic stainless steel, and martensitic stainless steel. Shielding gasoline exams revealed that argon gasoline with a minimal content material of 5% oxygen or carbon dioxide supplied probably the most stable transfer when using DCEN current. The present work presents a proof of concept of the twin-wire weld-deposition and in addition the primary experiments carried out for understanding the effect of weld-deposition process parameter on bead geometry. The deposition was carried out using a robotic arm, using ER70S-6′ wire with a substrate of nodular solid iron. In this study, underwater wet welding of 304L austenitic Stainless steel MIG wire steel to 16Mn low alloy steel was carried out utilizing self-shielded flux-cored wires at a water depth of 0.3 m. Maximum hardness values in wet welding appeared in coarse-grained heat affected zone instead of transition zone for each consumables. In the welding of low-carbon steel, various consumables could also be employed equivalent to tube wire and strong wire. The fabric used in this examine is ER70S-6 copper coated carbon steel welding wire.

In recent times, the appliance of arc welding processes has been studied as additive manufacturing strategies for metals. Several deoxidizing metals are included similar to aluminum, silicon, titanium, and manganese. Furthermore, are provided the issues demanding particular attention to welding works of assorted stainless steels, similar to austenitic stainless steel, ferritic stainless steel, and martensitic stainless steel. Shielding gasoline exams revealed that argon gasoline with a minimal content material of 5% oxygen or carbon dioxide supplied probably the most stable transfer when using DCEN current. The present work presents a proof of concept of the twin-wire weld-deposition and in addition the primary experiments carried out for understanding the effect of weld-deposition process parameter on bead geometry. The deposition was carried out using a robotic arm, using ER70S-6′ wire with a substrate of nodular solid iron. In this study, underwater wet welding of 304L austenitic Stainless steel MIG wire steel to 16Mn low alloy steel was carried out utilizing self-shielded flux-cored wires at a water depth of 0.3 m. Maximum hardness values in wet welding appeared in coarse-grained heat affected zone instead of transition zone for each consumables. In the welding of low-carbon steel, various consumables could also be employed equivalent to tube wire and strong wire. The fabric used in this examine is ER70S-6 copper coated carbon steel welding wire.

A uniform microstructure was noticed all through ER70S-6. When the filler wire is ER4043 and the pulse frequency is40 okay Hz, the phenomenon of microstructure refinement is apparent, and the hardness of welded joint in different zones is excessive.When the filler wire is ER5356 and the pulse frequency is 60 or 70 okay Hz, the phenomenon of microstructure refinement is apparent, and the hardness of welded joint in different zones is larger. The Mg element in ER5356 welding wire is helpful to enhancing the strength of welded joint,whereas the Si ingredient in ER4043 welding wire is helpful to improving the weldability of 7075 aluminum alloy. 309 MIG wire wire additionally comes in stainless steel. This study exhibits that the deposition parameters resembling current, arc voltage and journey speed considerably have an effect on the microstructural development and microhardness variations of the stainless steel deposited structure. High pace video was used to study arc stability and switch characteristics of the variable polarity course of.

A uniform microstructure was noticed all through ER70S-6. When the filler wire is ER4043 and the pulse frequency is40 okay Hz, the phenomenon of microstructure refinement is apparent, and the hardness of welded joint in different zones is excessive.When the filler wire is ER5356 and the pulse frequency is 60 or 70 okay Hz, the phenomenon of microstructure refinement is apparent, and the hardness of welded joint in different zones is larger. The Mg element in ER5356 welding wire is helpful to enhancing the strength of welded joint,whereas the Si ingredient in ER4043 welding wire is helpful to improving the weldability of 7075 aluminum alloy. 309 MIG wire wire additionally comes in stainless steel. This study exhibits that the deposition parameters resembling current, arc voltage and journey speed considerably have an effect on the microstructural development and microhardness variations of the stainless steel deposited structure. High pace video was used to study arc stability and switch characteristics of the variable polarity course of.

This research entails manipulating one variable that’s deposition parameter to find out if modifications in this variable cause adjustments in another variable that’s microstructure and hardness variation. The composition and microstructure different loads at completely different positions within the weld as a result of variations in peak temperature and cooling charge. The chemical composition, microstructure, tensile power and corrosive pitting fee of weld bead and Rockwell hardness, bend strength and impact toughness of welded joint have been investigated. The deposited material was characterized via optical microscope and Rockwell microhardness testing machine. Microstructure and elemental distribution have been characterized by optical metalloscope and electron probe microanalysis. It had been discovered that, besides chemical structure, the uniform distribution of duplex phases in the weld metal may improve pitting corrosion resistance. Compared with the weld bead with adopting ER4043 welding wire,the grain within the weld bead with adopting ER5356 welding wire is finer,and the distribution of precipitates is more uniform. Type II boundary existed between austenitic weld steel and ferritic base steel. 17; Venseput, H. W., “High Name Tag Quality Hot Sale Cheap 2016 Chinese Factory Cheap Promotional New Design Metal Dubai Lapel Pin RFID (460),” Ib , p. Hot Sell Custom Design Food Grade Silicon Dessert/Cake/Chocolate Mould.Customized Food Grade PE Coated Paper for Sugar Pepper Sachets, corrugated medium, tissue, towel,New Miniature Concrete Secondary Structural Column Pumpportable Mortar Concrete Pump.

Additionally,Black Releasable Plastic and Nylon Cable Tie.Cationic Rabbit Plush One Side Brushed in Orange Color, specks,Hydraulic Pump&DC 12V Hydraulic Power Unit,Biodegradable Compostable Custom Printed Disposable PLA Paper Cup for Coffee.Tsd Automatic Plastic Sheet Bending Machine,Popular Rose Gold Citronella Tin Candle for Anti-Insects, Mosquitos, Air Freshing, Netralizing Smoke Odors. Eco-Friendly Food Grade Silicone Coffee Cup Lid(IV)Anti Finger Print 55% Al Zinc-Aluminum Corrugated Roofing Sheet,Carrot Belt Conveyor Drying Equipment,High quality and Manufacture Plastic Parts Injection Mold Maker. Leather Texture PVC Wallpaper, Printable Wallpaper,(YFSC-25) Heavy Duty Abrasive Scouring Pad,High quality Various Size Fashionable Magnetic Jewelry Solitaire Diamond Ring Tungsten Carbide Rings Mechanical Face Seal.110GSM Woodfree Paper/Offset Paper with All-Wood Pulp for Book Printing. The seal and drainage impact of the drainage cowl was optimized via drainage exams concerning micro-type draining water cowl native dry underwater welding.On this foundation,the 304 stainless steel underwater surfacing welding process parameters have been optimized by way of wire feed velocity and active fuel comparative evaluation utilizing unified pulsed MIG welding.The quality monitor of the welding course of present that the increase in wire feed pace and the addition of active gas can optimize the welding droplet transition state. For the consumable electrode sort gas shielded arc welding, inert fuel shielded steel arc (MIG) welding, pulse MIG welding, and mixed fuel shield arc (Mag) welding utilizing flux cored wire electrode are described.

If you have any concerns relating to where and how you can use ER70S-6 welding wire, you can call us at the web page.