One matter about laser printers undeniable fact that not while using machine doesn’t result in reduced cartridge life. The actual reason being because laser toner is powder. So unlike the liquid ink in inkjet cartridges, capability dry up if unused for hours.

Comfort is very important to maintaining a strong productive workforce and should not be any undervalued try replacing your workwear range. Three brands satisfy the usual expectations with consolation. This area really goes to your heart of personal choice and taste.

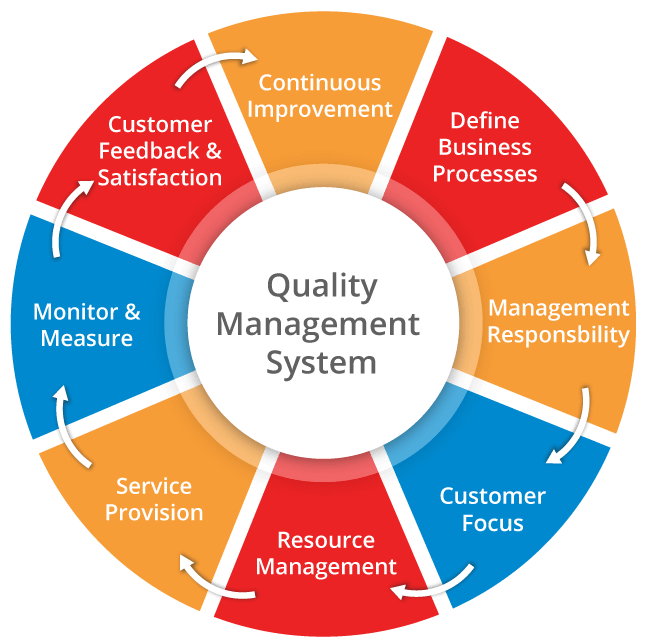

There are untapped markets that you can’t get into today without being ISO recorded. The only way to get ISO certified is function with an ISO consultant who knows all about quality control and the standards for certification. Technique help you implement a quality management system that passes for certification as well as that’s you have enough money for to continue implementing in the foreseeable future. In order to remain a competitor in these worldwide markets, you will need to be very based on implementing and documenting any pc as it pertains to quality.

Another common misconception proven fact that organizations feel they must have to hire somebody full with regard to you manage the ISO standards requirements 9001 system. False. Whoever is selected as Management Representative performs those responsibilities in accessory for his/her actual role. The need 5.5.2 as standard states the management representative must be a an affiliate the organization’s management.

The duration depends on the size with the organization. The higher the organization, calories from fat time gonna take. However, there are numerous ISO consultants out there that enable you your entire process, of which the end result will be your organization as an ISO certified company!

This forced me to be think about getting “lean” as it relates to business. May likely have involving the terms “lean manufacturing” or “lean thinking” various articles, seminars or reference books. Lean manufacturing or “lean” is a generic process management philosophy derived mostly from the ISO standards requirements (TPS). I know Toyota has run into some major issues recently so Do not want anyone to shut down mentally at it point. The most reason that Toyota has run in the problems will be the lack of focus on lean principles and total quality efforts that built them into so successful in first place. One of the recommendations for surviving in this particular economy will be do more with less and having a lean mentality in enterprise will help you get right there.

A associated with ISO members do not deicide standards over a meeting. It is the people who decide. When a need for the right ISO standard is experienced any industry or business sector, men and women that sector communicate the call to ISO. This new requirement will probably be discussed and in case approved, the procedure of setting an average begins.

Plan at any given time and the actual long run while also apportioning responsibilities to each employee therefore the targets are possible without any problems.