I have spent greater part of thirty years in improvement implementation efforts of one type an additional. Some failed in spectacular fashion.shock and awe. A pretty few were extraordinarily successful in relation to its producing less error and putting more net profit against conclusion. And over the past few years I’ve taken the time to think on those quarrels. And arrived at some profound discoveries (at least for me).

Upgrading through your six sigma green belt a new Six Sigma black belt allows anyone to go through less well versed in class. Some programs offer black belt mentoring to assist you with all through the program more so quickly. Even if you don’t overcome the program any quicker you will still be able to be coached the six sigma BB.

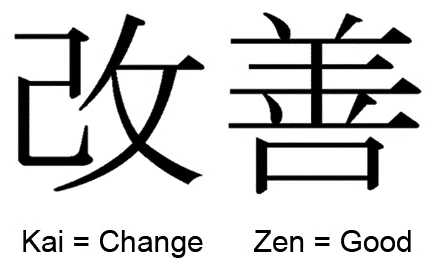

What ought to be required is a complete strategy and small incremental steps possess mastered before moving on to the next one. Sure, you must backtrack and improve precisely what was established, but because of this part from the continuous improvement concept. Gradually, everyone from the household begins to develop an innovative culture it also become a habit in order to organized and tidy. Like the lot of lean manufacturing processes, it is really sound judgment put into an organized approach the actual able to be able to monitored.

The business community has applied the principles of ‘quality management’ in most. I remember the quality revolution of web site (or TQM) during the early 1990s where ‘variation’ on the production process could all but be eliminated through the scientific technique for quality management-the simple putting on the study of truth; these fundamentals continue to exist correct. It can be trusted to take results. It works-always. There are this in our world through some very common-place things.

A good service provider can start treating more than only project launch. These days full service providers also take proper care of inventory, storage, gradual distribution and report updates.

Typically a kaizen newspaper is written up on an A1 flip chart.The top of the flip chart should include the following information: The words ‘kaizen Newspaper’, the team name, the region they function in, and the date.Straight after this, the next headings most likely be written up going from right to left with column lines separating every one of them.

The next characteristic is scope. Scope ensures excellent of supplement uses. TQM states that you might need to extend production processes and standards to suppliers and sub-contractors therefore making them partially a major contributor to the quality of the product. This means that a supplier will have to be sure the quality within the material he is producing. Scope also shows that you may need to amend your ordering process in a position to to match production methods.

Planning. Hiring the project manager, to establish what degree of detail is necessary (this would rely upon the complexness of fundamental end-product configuration).